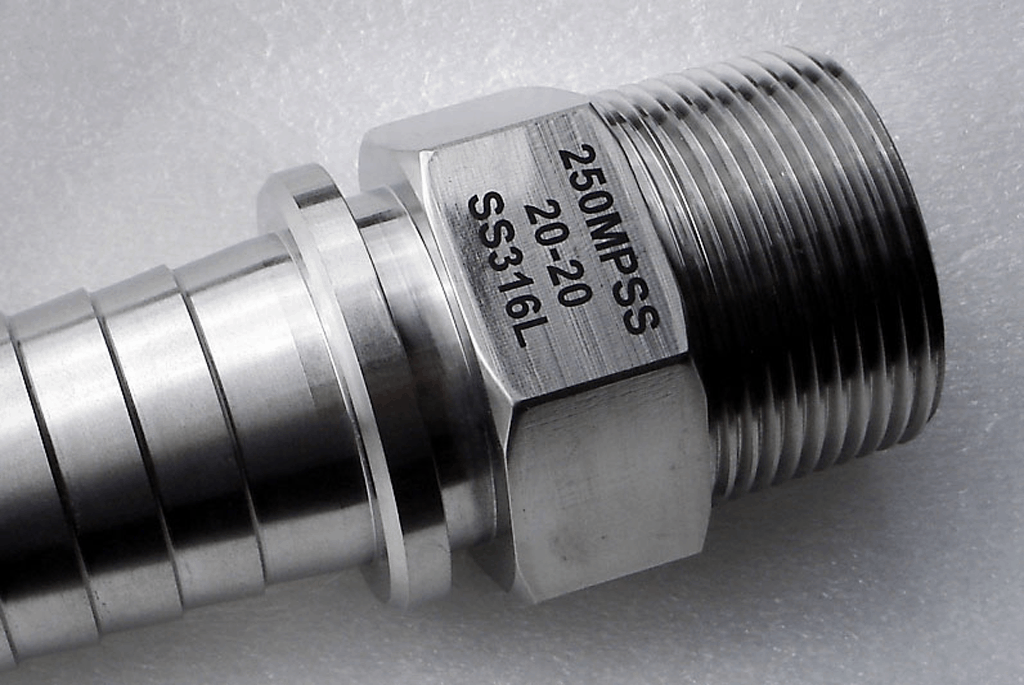

With our fiber laser engraving system, South Shore Manufacturing Company is prepared to manage all of your direct part marking needs. We leverage our laser marking and engraving system to add permanent information that identifies an item for total lifecycle traceability. Our laser marking capabilities enable us to provide clear markings, such as serial numbers, lot numbers, unique identifiers, barcodes, logos, and other images, graphics, and data that retain their legibility, even when exposed to challenging environmental conditions.

Specifications

- Engraving Capability

-

Barcoding

Micro

Serializing

- Materials

-

Alloy Steel

Aluminum

Brass

Carbide

Stainless Steel

Steel

Titanium

-

Maximum Engraving Depth: 0.010 in

Maximum Engraving Height: 6.0 in

Maximum Engraving Width: 6.0 in

Laser Type: Fiber

Power Rating: 30 W

- Production Volume

-

Prototype

Low Volume

High Volume

Blanket Orders

- Lead Times

-

Quoted on Job by Job Basis

Emergency Services Available

Rush Services Available

- Efficiency

-

Lights Out Manufacturing

Lean Manufacturing

-

As a non-contact marking method, laser marking does not alter the surface quality or affect the precision or integrity of a part in any way. We engrave text, symbols, and graphics on flat, curved, or irregular surfaces and create fine markings that are permanent and durable. Lasers produce dark-colored marks on steel and stainless steel or a white mark on colored anodized aluminum. Other materials we laser mark include brass, carbide, and titanium. We can add micro-sized text or symbols measuring up to 6.0” high x 6.0“ long, our maximum engraving depth is .010”, and we can also engrave reverse images and lettering inside mold cavities.

Federal laws and regulations stipulate that parts found in automobiles, aircraft, military equipment, medical devices, electronics, and many other critical products contain information for tracking and traceability. Laser markings also aid in product authentication, add essential information about certifications, and facilitate record keeping throughout the supply chain and in the part’s end-use application. With our laser marking capabilities, we handle small orders as well as high volumes of parts, including those that need serialization. Contact us directly to learn more about our laser marking capabilities or to get a quote.

Additional Information

- Industry Focus

-

Aerospace

Automation

Automotive

Biomedical

Biopharmaceutical

Biotechnology

Chemical Manufacturing

Commercial

Communications

Consumer Goods

Dental

Defense Industry

Electrical

Electronics

Energy

Extrusion Dies

Firearms

Food Production

Food Handling

Food Processing

Food & Beverage

Industrial

Injection Molding

Laboratory

Machine Tools

Machinery

Manufacturing

Marine

Medical

Medical Devices

Military

Molding

Nuclear

Optical

Packaging

Pharmaceutical

Pumps

Railroad

Research

Robotics

Semiconductor

Specialty Machinery

Surgical

Tool & Die

Universities & Learning Institutions

- File Formats

-

- AutoCAD (DWG, DWZ)

- DXF (Drawing Interchange Format, or Drawing Exchange Format)

- IGES (Initial Graphics Exchange Specification, ANSI File Format)

- PDF (Portable Document Format)

- SolidWorks (SLDPRT, SLDDRW, SLDDRT)

- STEP (Standard for the Exchange of Product Model Data)