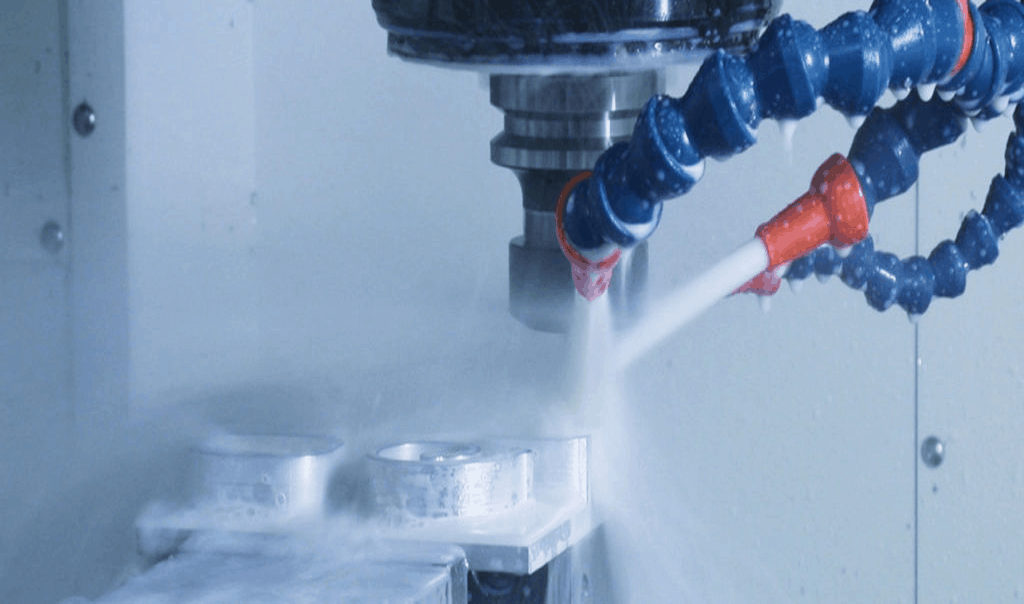

At South Shore Manufacturing Company, we offer CNC machining services for the production of close-tolerance metal parts. We have the ability to produce components with the most technical and precise quality criteria. By combining our engineering and machining capabilities, we can manage the progression from prototype parts to production level manufacturing. Quality-driven, we take extreme measures to ensure parts conform exactly to customer specifications. We also plan and schedule work to meet strict production deadlines.

Our CNC Machining Capabilities

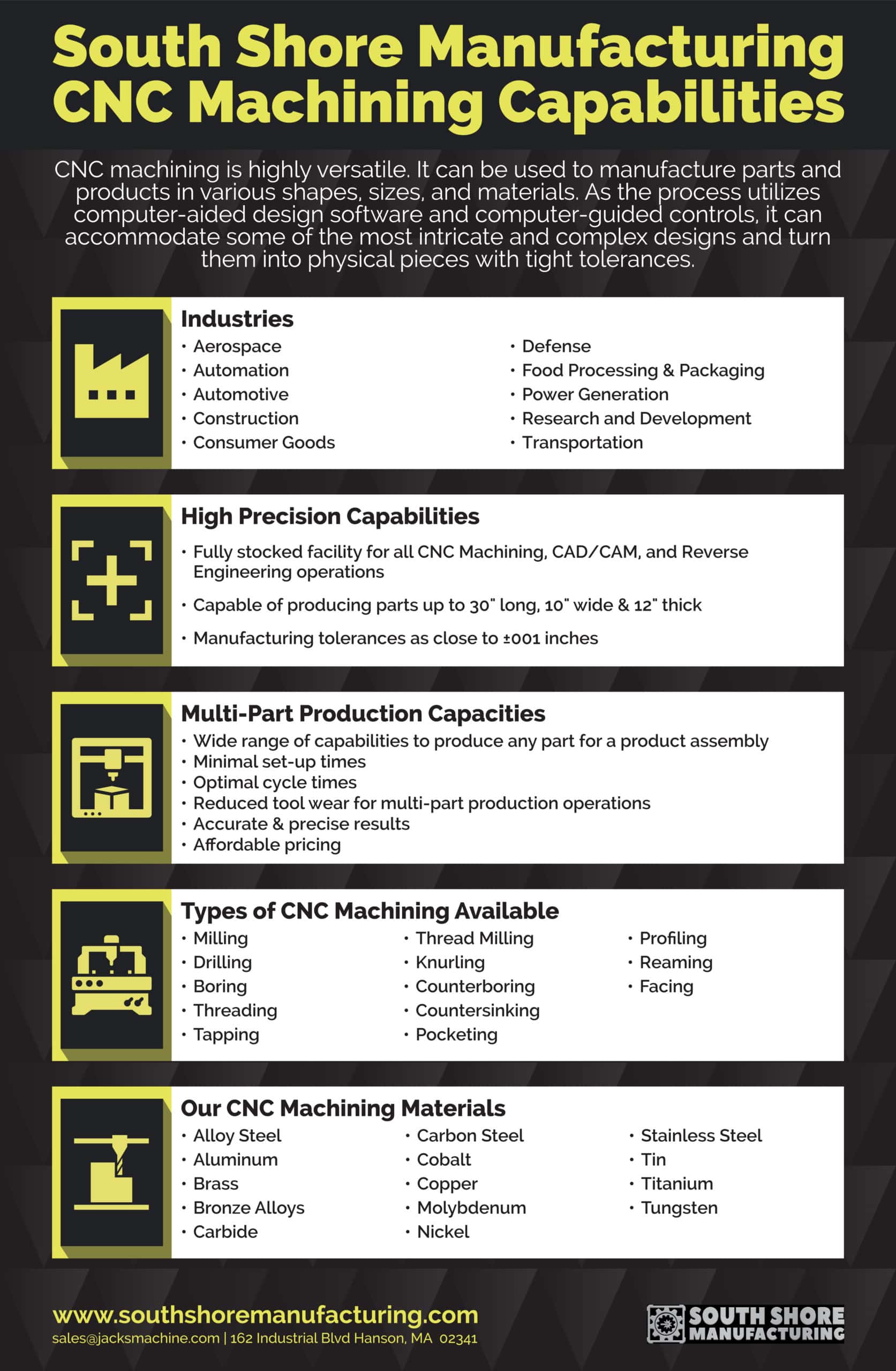

CNC machining is highly versatile. It can be used to manufacture parts and products in various shapes, sizes, and materials. As the process utilizes computer-aided design software and computer-guided controls, it can accommodate some of the most intricate and complex designs and turn them into physical pieces with tight tolerances.

Typical industries that rely on machined components include:

- Aerospace

- Automation

- Automotive

- Construction

- Consumer Goods

- Defense

- Food Processing

- Packaging

- Power Generation

- Research and Development

- Transportation

High Precision CNC Machining Capabilities

Our CNC machining facility is fully stocked with everything we need for our computer numerical control (CNC) machining, computer-aided design/manufacturing (CAD/CAM), and reverse engineering operations. This equipment allows us to produce parts up to 30 inches long by 10 inches wide by 12 inches thick in volumes for prototype, low-volume, high-volume, and blanket orders. By carefully choosing the machine tools and optimizing feed rates and cutting speeds, we can achieve manufacturing tolerances as close ±.001 inches.

Multi-Part Production Capacities

Our wide range of machining capabilities allows us to produce virtually all of the parts needed for a product assembly. By using data taken directly from CAD files to program our CNC machines, we can minimize set-up times, optimize cycle times, and reduce tool wear for these multi-part production operations, which enable us to achieve accurate and precise results, meet production deadlines, and keep the unit costs as low as possible.

Types of CNC Machining Available

At South Shore Manufacturing, we offer an extensive range of CNC machining services, including:

- Milling

- Drilling

- Boring

- Threading

- Tapping

- Thread Milling

- Knurling

- Counterboring

- Countersinking

- Pocketing

- Profiling

- Reaming

- Facing

For more information regarding the types of CNC Machining processes available at South Shore Manufacturing, please visit our contact us page and fill out a form.

Our CNC Machining Materials

We accommodate a variety of metals in our CNC machining operations. Our standard material offerings include:

- Alloy Steel

- Aluminum

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Copper

- Molybdenum

- Nickel

- Stainless Steel

- Tin

- Titanium

- Tungsten

CNC Machining Services from South Shore Manufacturing

When you choose South Shore Manufacturing as your CNC machining partner, you can rest assured that your machined parts and products will meet the highest quality standards. Our team has extensive experience machining high-value components for customers in demanding industries, such as aerospace, medical device components, tool and die, semiconductor, firearms, robotics, and other markets with strict quality specifications and standards.

To learn more about our CNC machining capabilities, contact us today. To discuss your requirements with one of our experts, request a quote.