What to Look for When Choosing a Waterjet Cutting Company

Leave a CommentChoosing the right waterjet cutting company is paramount when embarking on a project that requires precision cutting of various materials. Factors like experience, capabilities, customer service, quality, and turnaround time need careful consideration. With incredible versatility across industries, waterjet technology has many commercial and industrial applications. However, not all waterjet companies are equal in their […]

What Is Waterjet Cutting?

Leave a CommentWaterjet cutting is a manufacturing process where highly pressurized water is fired through a ruby or diamond nozzle into a mixing chamber. The pressure makes a vacuum and pulls garnet sand into the stream, which is then shot at the object being cut. The sand particles wear down, or cut, the material. Waterjet cutting is […]

Wire Electrical Discharge Machining Machined Parts for Medical Devices

Leave a CommentPatient lives and well-being depend on high-quality and reliable medical equipment. Advanced medical device manufacturers comply with high standards and have no margin for error when machining medical components. Manufacturers rely on medical machining, a type of CNC machining for medical devices that can produce micro-medical components and parts. However, small-scale and micro-machining can challenge […]

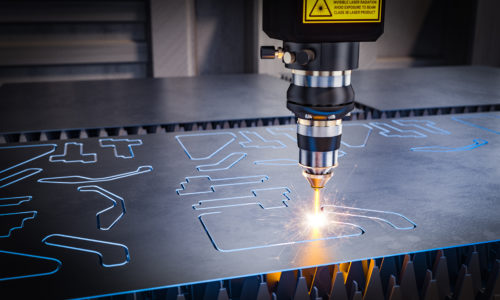

Wire EDM Cutting vs Laser Cutting

Leave a CommentThere are many techniques, technologies, and methods for cutting and shaping components during manufacturing, and many of these methods utilize similar functions to create components. These similarities can make it challenging to determine which technique is best suited for your particular application. For example, wire EDM cutting and laser cutting are very similar in that […]

Wire Electrical Discharge Machining Cutting for High-Quality Finishing

Leave a CommentElectrical discharge machining, or EDM, is a precision manufacturing technique that uses electricity to shape metal workpieces. This method uses brass wire to create sparks that vaporize the metal they contact. In wire EDM, the electrode is a length of thin single-strand wire that, when applied continuously, generates clean cuts with a smooth, high-quality surface […]

CNC Machining vs 3D Printing

Leave a CommentSouth Shore Manufacturing is renowned for its high-quality computer numerical control (CNC) machining services and having the best close-tolerance metal parts. We use versatile CNC machining capabilities to manufacture various products and parts of different shapes, sizes, and materials. Even if you need the most complex, intricate design, our computer-aided controls, computer-aided design software, and […]

3 Reasons Why Water Jet Cutting Is the Right Choice for Your Next Metal Fabrication Project

Leave a CommentWater jet cutting is a fabrication process that relies on the principles of erosion. It involves pressurizing water—sometimes mixed with abrasive media (e.g., garnet)—to up to 392 MPa and projecting it from a small-bore nozzle. The result is a high-pressure, high-speed stream of water (i.e., water jet), which can be used to cut a wide […]

Laser Cutting vs. Water Jet Cutting

Leave a CommentCutting is an important step in nearly every manufacturing project. It makes raw material easier to handle and helps it achieve the proper shape and size. There are many cutting methods available, each of which has distinct advantages and disadvantages that make it suitable for different applications. Two of the most commonly used processes to […]

How Does Wire Electrical Discharge Machining Work?

Leave a CommentWire electrical discharge machining, also known as wire EDM, is a contact-free machining method that uses a thin metal wire to conduct an electrical current. The current creates sparks, which are used to accurately cut a workpiece into the pre-programmed design. At South Shore Manufacturing, we offer high-quality wire EDM services to meet the needs […]

Jack’s Machine Company is Now South Shore Manufacturing

Leave a CommentJack’s Machine Company is now doing business as South Shore Manufacturing. As of the past few years, Jack’s Machine Company is under new leadership and has expanded its manufacturing capabilities and capacity beyond the core competence of Wire EDM. The company’s focus is still on Wire EDM and the company has also expanded its in-house […]