Wire Electrical Discharge Machining Cutting for High-Quality Finishing

Leave a CommentElectrical discharge machining, or EDM, is a precision manufacturing technique that uses electricity to shape metal workpieces. This method uses brass wire to create sparks that vaporize the metal they contact. In wire EDM, the electrode is a length of thin single-strand wire that, when applied continuously, generates clean cuts with a smooth, high-quality surface finish.

Because it relies on electricity, wire EDM can only be used on conductive metals like titanium, steel, aluminum, and copper. This method is ideal for materials that are challenging to cut using conventional methods. These materials include components with intricate details such as tight slots or inside corners with small radii. Wire EDM is also the preferred method to machine high rockwell hardness metals, which are otherwise slow and expensive to process.

What Is Wire Electrical Discharge Machining Metal Cutting?

Wire EDM cutting is a subtype of electrical discharge machining that uses a fine metal wire to cut conductive metals. The process takes place in a specialized machine that keeps the wire and the workpiece submerged in deionized water. This fluid serves as insulation to prevent premature discharge, clear debris, and cool the wire and workpiece.

During cutting, the electrified, CNC-controlled wire approaches the workpiece until it generates a spark. These controlled sparks can produce temperatures between 8,000 and 12,000 °C, which vaporizes and disperse the material into the surrounding fluid. The discharge process repeats until the desired cuts are achieved. Since these sparks also slowly erode the wire, the EDM machine constantly unspools fresh wire during operation.

Applications of Electrical Discharge Machining Wire Cutting

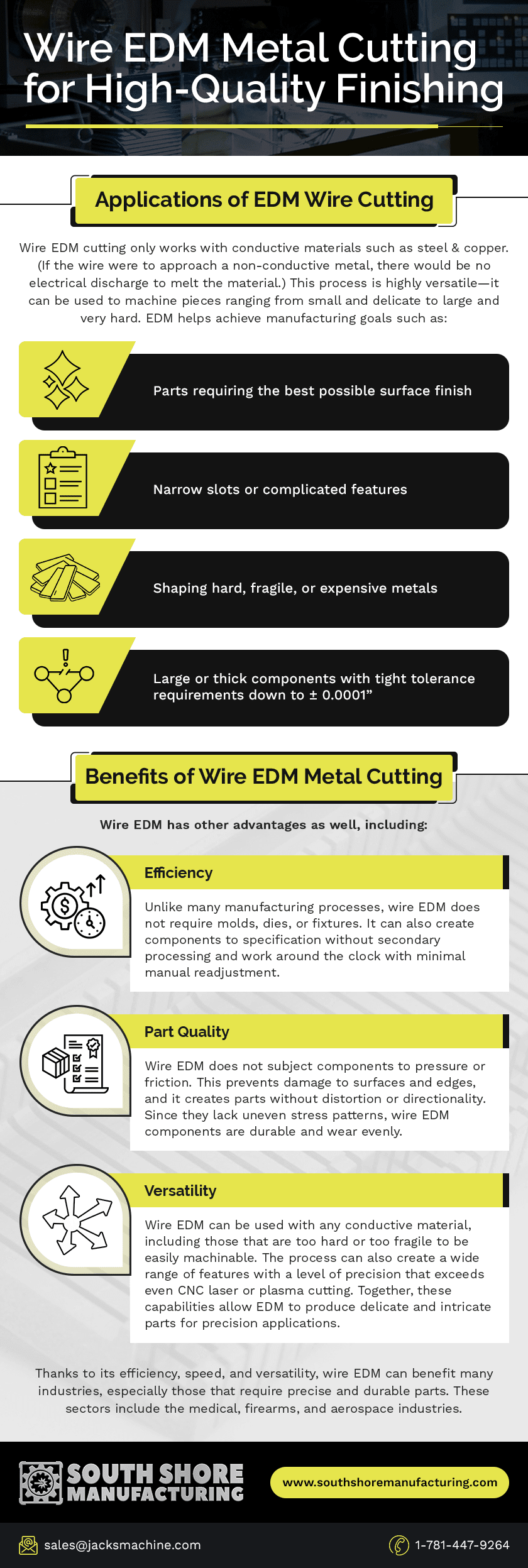

Wire EDM cutting only works with conductive materials such as steel and copper. (If the wire were to approach a non-conductive metal, there would be no electrical discharge to melt the material.) This process is highly versatile—it can be used to machine pieces ranging from small and delicate to large and very hard. EDM helps achieve manufacturing goals such as:

- Parts requiring the best possible surface finish

- Narrow slots or complicated features

- Shaping hard, fragile, or expensive metals

- Large or thick components with tight tolerance requirements down to ± 0.0001”

Wire Electrical Discharge Machining Cutting Surface Finish

Wire EDM is well known for creating even, sometimes mirror-like surface finishes. These results are possible because the process involves eroding rather than cutting the metal.

With conventional cutting, hard materials generate so much friction that they require slow passes with special cutting tools. Similarly, brittle materials often lose material in uneven flakes that must later be smoothed with a grinder.

With wire EDM, sparks remove material without direct contact, friction, or directionality. This avoids creating a lay or warping the metal, and material hardness or brittleness does not affect the final results. By avoiding contact with the material, wire EDM can quickly and effectively achieve superior surface finishes regardless of the metal’s physical properties, thus reducing the need for secondary processing.

How Manufacturers Achieve an Ideal Surface Finish with Wire Electrical Discharge Machining

To achieve the most precise surface finish, manufacturers cut materials in multiple stages. The first rough cut uses a highly charged electrode to remove a large amount of material and establish the general shape of the component. Then, with each subsequent pass, the voltage is modified to remove less and less material, refining the surface to remove any imperfections from the initial passes. The amount removed depends on the wire’s thickness and charge, but the most precise passes can remove as little as 0.0001” of metal. Eroding the material in this progressive manner eliminates the irregularities associated with other cutting methods so that components are ready to ship without additional grinding, polishing, or deburring.

At South Shore Manufacturing, we use these techniques to achieve surface finishes as smooth as 8 μin. Metals we work with include stainless steel, titanium, Inconel®, Monel®, platinum, silver, gold, aluminum, and more.

Benefits of Wire EDM Metal Cutting

Surface finish is a critical concern for many manufacturers. Irregularities on a component’s surface generate unnecessary friction and make the component more prone to wear. A smooth surface finish not only looks better, but it also performs better while protecting nearby components from damage. Wire EDM is a cost-effective way to address these concerns, as it creates an optimal surface finish with little to no secondary processing.

Wire EDM has other advantages as well, including:

- Efficiency: Unlike many manufacturing processes, wire EDM does not require molds, dies, or fixtures. It can also create components to specification without secondary processing and work around the clock with minimal manual readjustment.

- Part quality: Wire EDM does not subject components to pressure or friction. This prevents damage to surfaces and edges, and it creates parts without distortion or directionality. Since they lack uneven stress patterns, wire EDM components are durable and wear evenly.

- Versatility: Wire EDM can be used with any conductive material, including those that are too hard or too fragile to be easily machinable. The process can also create a wide range of features with a level of precision that exceeds even CNC laser or plasma cutting. Together, these capabilities allow EDM to produce delicate and intricate parts for precision applications.

Thanks to its efficiency, speed, and versatility, wire EDM can benefit many industries, especially those that require precise and durable parts. These sectors include the medical, firearms, and aerospace industries.

Wire EDM Metal Cutting at South Shore Manufacturing

South Shore Manufacturing has specialized in precision wire EDM manufacturing for nearly 40 years. Today, we are the largest EDM provider in New England, equipped with a 10,000-square-foot facility and 16 wire EDM machines. Our staff draws on cutting-edge equipment, advanced automation, and extensive industry knowledge to deliver components on time and to precise specifications.

To learn more about our production capabilities, contact us or request a quote today.