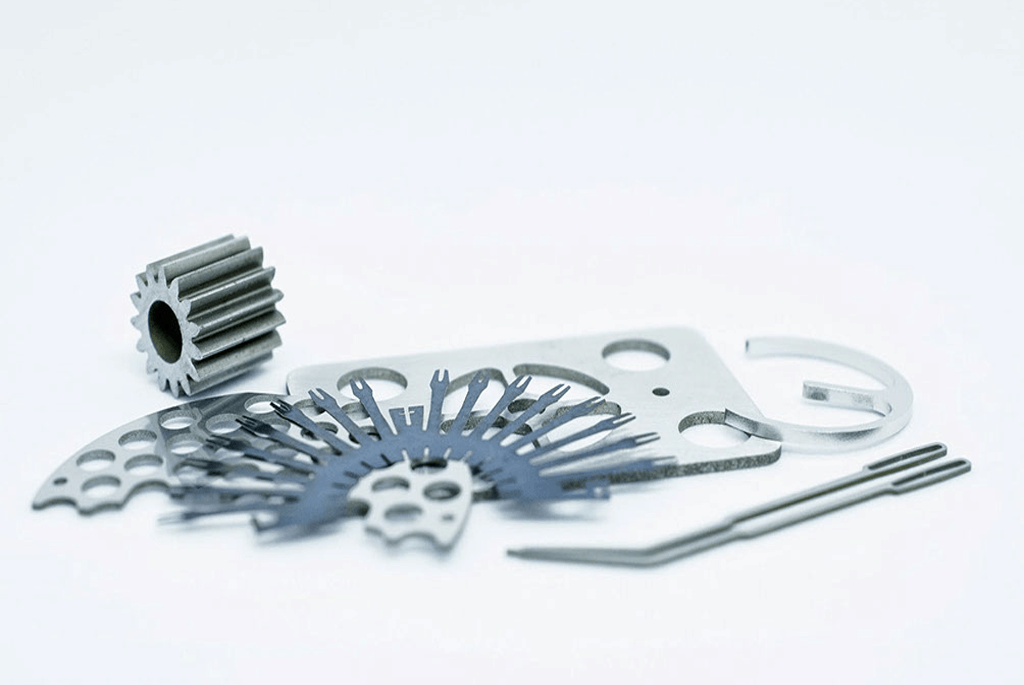

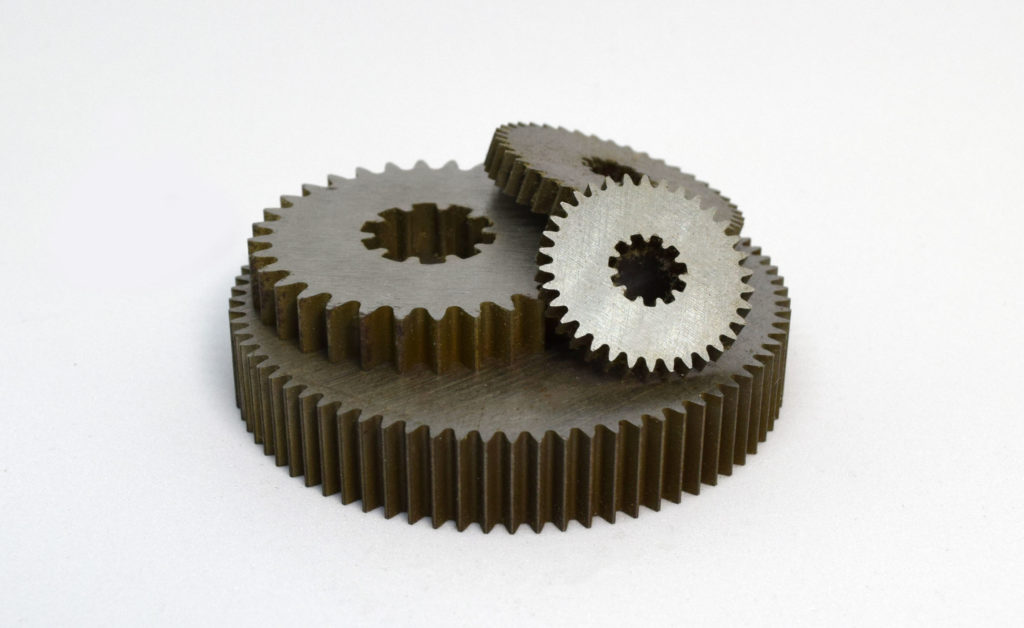

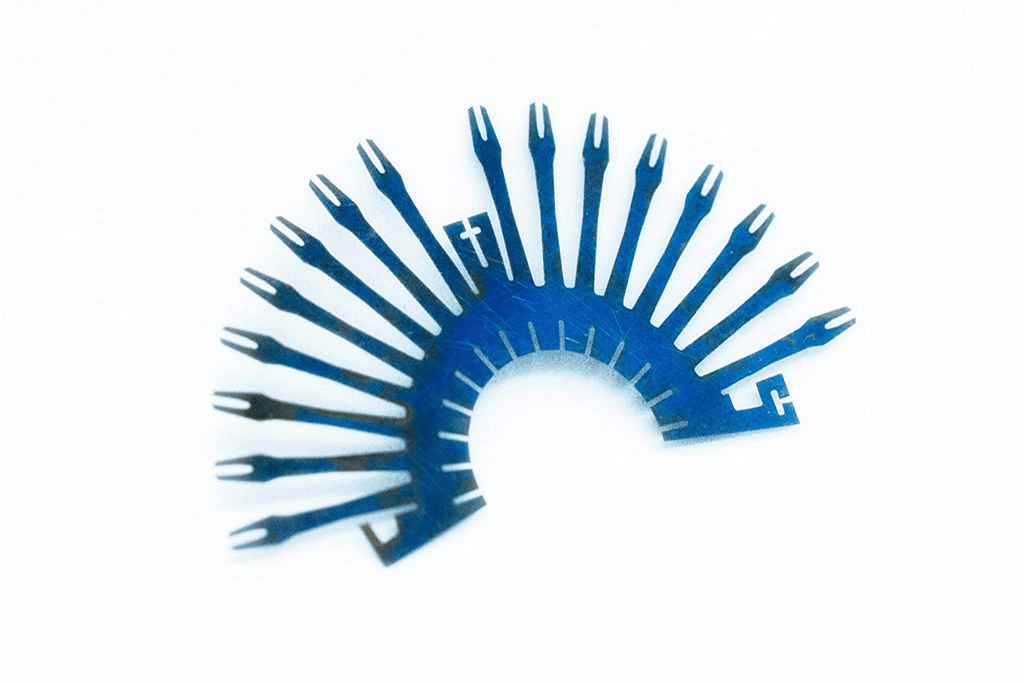

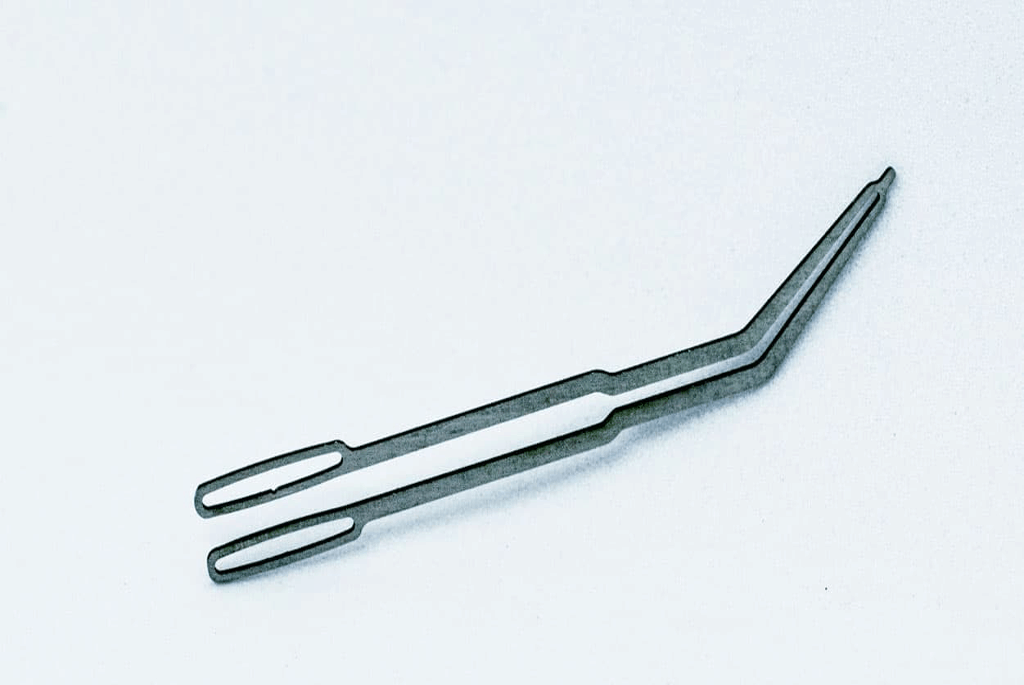

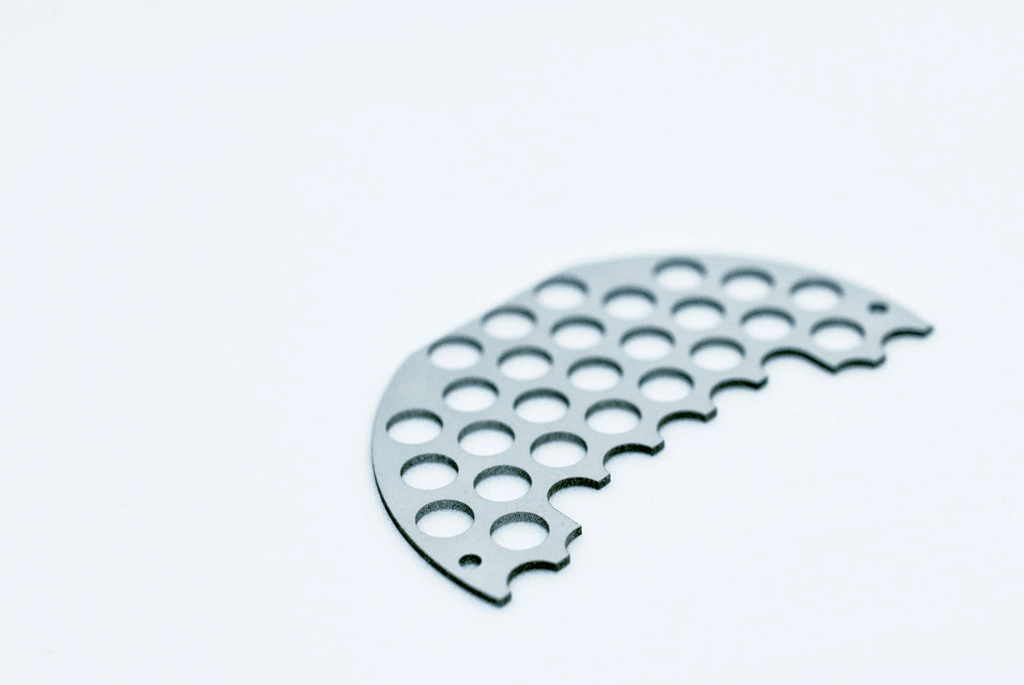

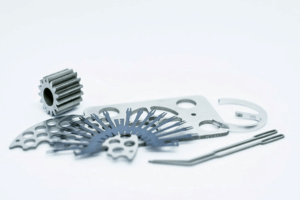

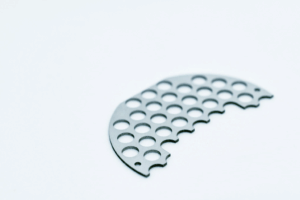

South Shore Manufacturing specializes in EDM machining services, a capability that can effectively remove or cut materials from a substrate. Our focus is precision wire cutting EDM, an exceptionally accurate machining method that can achieve optimal results using thermal energy on stiff, more rigid materials that traditional tooling can’t handle.

Extensive Range of Wire EDM Machining Services

Our wire cutting service is the most cost-effective way of accomplishing complex shapes, even when hard metals and tough alloys are involved. We specialize in producing superior quality components through our range of EDM machining services, ensuring we employ the proper technique to achieve the parts needed for a particular application.

The various types of high-performance EDM machining processes we offer include:

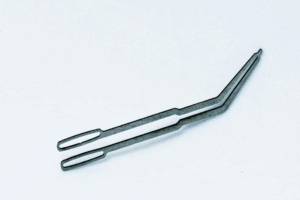

- Fine wire EDM

- EDM drilling

- Precision wire EDM

- Wire EDM

- Prototyping

At South Shore Manufacturing, we’re proud to provide industry-standard products to improve your bottom line. We can work on conductive and exotic materials from fine wire EDM to wire EDM service.

Some materials where wire EDM is the best option:

- Titanium

- Silver, Gold, and Platinum

- Copper, Brass, and Bronze Alloys

- Carbon and Stainless Steel

- Aluminum and Tin

- Inconel® and Monel®

- Iron, Nickel, and Molybdenum

If you can’t find your desired material on the list, don’t hesitate to contact us so that we can discuss your specific material requirements.

Common Applications of Wire Cutting EDM

We employ our wire EDM services to manufacture high-performance and accurate outcomes for numerous applications seamlessly and in the most demanding industries.

Some examples are as follows:

- Medical devices: Fine wire EDM is used to manufacture implants and other everyday medical devices and instrumentations.

- Aerospace components: This industry uses hard and thick metals, which is difficult to machine. Fortunately, our wire cutting service can cut through these materials with high accuracy and zero distortions.

- Prototype manufacturing: EDM machining services are easy to set up with minimal preparations. It’s an ideal capability for prototype production, especially for pre-production.

- Firearms: Firearm production requires higher accuracy due to its incredibly complex geometries. They also have extremely tight tolerances and need a machining process to deliver clear-cut results. Our precision wire EDM service can accomplish these outcomes while ensuring there are no errors in the end product.

Choose Expert EDM Machinists to Work on Your Projects

South Shore Manufacturing can help you if you want a new design to come to life or for prototyping purposes. We can produce parts and components on time with our vast range of EDM machining services and capabilities, whether it uses fine wire EDM or a simple wire EDM method.

If you want to know more about our reliable wire EDM service, don’t hesitate to contact us today. Our team can give you a quick quote that won’t break the bank but can meet your prerequisites!

Specifications

- Processes

-

- Electrical Discharge Machining (EDM) Drilling

- Fine Wire Electrical Discharge Machining (EDM)

- Precision Wire Electrical Discharge Machining (EDM) Services

- Wire Electrical Discharge Machining (EDM)

- Prototyping

- Cutting Axis

-

2-Axis

4-Axis

- Materials (Metals)

-

Alloy Steel

Aluminum

Brass

Bronze Alloys

Carbide

Carbon Steel

Cobalt

Copper

Iron

Molybdenum

Nickel

Stainless Steel

Tin

Titanium

Tungsten

- Materials (Exotic & Precious Metals)

-

Gold

Inconel®

Invar®

Iridium

Kovar®

Monel®

Niobium

Palladium

Platinum

Silver

Superalloys

Tantalum

-

Maximum Length: 33.0 in

Maximum Width: 20.0 in

Maximum Thickness: 16.0 in

Surface Finish: 8 µin

Tolerance: (±) 0.0001 in

- Additional Capabilities

-

- Computer Aided Design (CAD) Services

- Computer Aided Manufacturing (CAM) Programming Services

- Reverse Engineering

- Production Volume

-

Prototype

Low Volume

High Volume

Blanket Orders

- Lead Times

-

Quoted on Job by Job Basis

Emergency Services Available

Rush Services Available

- Efficiency

-

Lights Out Manufacturing

Lean Manufacturing

-

Our EDM department houses multi-axis EDMs with fine wire and EDM drilling capabilities. We uphold the maximum level of precision when creating parts from conductive metals, including the hardest and most difficult to machine exotic alloys. Our largest capacity machine features a 33.0” long x 20.0” wide x 16.0” deep work envelope. Without an EDM, some parts would be impossible to machine, but with our EDM capabilities, we can produce intricately detailed shapes, cut at odd angles, make sharp corners, form delicate contours, and machine thin walled features and internal tapers. CNC operation enables us to attain a very high level of repeatable accuracy – we uphold tolerances as close as ±.0001”, create surface finishes as fine as 8 μin. and produce smooth, burr free edges.

Whether a project consists of one-of-a-kind die sets, a small volume of precision parts, or scaled up production of high-value parts, we have the resources to accommodate any request. We offer fast turnaround times and have an excellent track record for on-time delivery. As a precision manufacturing company, we emphasize quality at every stage of production to ensure parts conform exactly to customer specifications. To learn more about our wire EDM capabilities or any of our other services, contact us directly.

Additional Information

- Industry Focus

-

Aerospace

Automation

Automotive

Biomedical

Biopharmaceutical

Biotechnology

Chemical Manufacturing

Commercial

Communications

Consumer Goods

Dental

Defense Industry

Electrical

Electronics

Energy

Extrusion Dies

Firearms

Food Production

Food Handling

Food Processing

Food & Beverage

Industrial

Injection Molding

Laboratory

Machine Tools

Machinery

Manufacturing

Marine

Medical

Medical Devices

Military

Molding

Nuclear

Optical

Packaging

Pharmaceutical

Pumps

Railroad

Research

Robotics

Semiconductor

Specialty Machinery

Surgical

Tool & Die

Universities & Learning Institutions

- File Formats

-

- AutoCAD (DWG, DWZ)

- DXF (Drawing Interchange Format, or Drawing Exchange Format)

- IGES (Initial Graphics Exchange Specification, ANSI File Format)

- PDF (Portable Document Format)

- SolidWorks (SLDPRT, SLDDRW, SLDDRT)

- STEP (Standard for the Exchange of Product Model Data)